SmartMotor™ 101

Knowledgebase

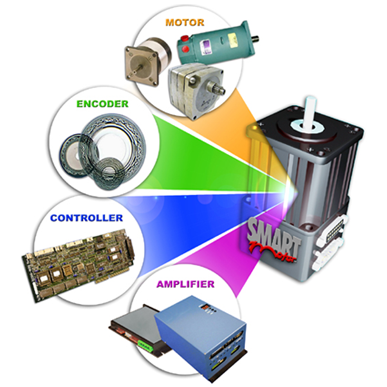

What is a SmartMotor™?

The Moog Animatics SmartMotor™ is a complete, compact, and user-friendly integrated motion control system that actually meets the textbook definition of a robot. Our line of advanced rotary and linear motion control products features the ability to perform multi-axis motion, including stand-alone coordinated motion. While priced similarly to other integrated servos, the SmartMotor™ brings real-world additional savings to the machine builder by eradicating other expensive and complicated elements in the machine, such as PLCs, sensors, I/O Blocks, and control cabinets. Additional axes can be easily added in the field, bringing additional processing power, but without parallel growth of existing cabinet size.

This simplicity and ease of use goes beyond just “compactness;” it results in overall reduced machine development time (shortening time-to-market), lower total machine cost, greater field reliability, and simplified machine design and build time, eliminating heavy procurement and support activities.

Not Just a Product…

What makes the Moog Animatics SmartMotor™ the most powerful integrated motor in the industry, by far, is its unique ability to control an entire machine. The SmartMotor™ is not just a product; it is a byproduct of an innovative design philosophy. The unsurpassed combination of programmability ease, networking capability, highly flexible and expandable I/O and high power density servo performance is exactly what you can expect from this pioneer and recognized global leader of truly integrated motion control.

By far, the greatest benefit of using the SmartMotor™ is that it lets you trump your competition by getting a dominant product to market weeks or potentially months sooner. Will your new machine design be rooted in old PLC technology, or will you take advantage of Moog Animatics SmartTechnology™ to gain a dramatic savings in time and money that will put you miles ahead of your competition?

Let our global network of factory-trained Automation Solution Providers show you how.

“Moog Animatics SmartMotor™ is by far the most powerful Integrated Motor in the industry because of its unique ability to control an entire machine.”