Concepts and Capabilities of the Animatics Product Range

Modes of Operation

Open Loop directional control of power to the motor windings. In this mode, the motor has knowledge of encoder position but does not use it for motion. The motor will increase speed until its commanded torque equalizes with load torque. If Load torque decreases, shaft speed will increase. If load torque increases, shaft torque will decrease. In a static condition, force applied will be proportional to commanded torque.

Closed Loop speed control based on position over time, not frequency. This means that from the initial command to begin motion, the controller keeps track of what the actual position should be.

If load momentarily increases beyond limits of the motor, shaft speed will be slightly reduced. If the load decreases back to within the capabilities of the motor, the shaft speed will increase beyond commanded speed in order to catch up to where it should have been had a constant velocity been maintained.

Position Mode:

Closed Loop control based on encoder feedback. All position mode moves are classified as either relative or absolute mode. Relative Mode means the motor is commanded to move a set distance in either direction relative to where the shaft is at the time.

Absolute Mode means the motor is commanded to move to a specific location regardless of initial position.

The motor will follow a standard step and direction input signal. A ratio of internal encoder counts to incoming pulses may be used. The Step Input can also be used as a high speed counter.

The motor will follow a standard quadrature incremental encoder bi-directionally. A ratio of internal encoder counts to external encoder counts may be used.

Includes separate ascend, slew and descend pre-defined distances that may be defined off of either controller1 or follower1 encoder values for enhancing applications such as high speed winders.

1. Moog Animatics has replaced the terms “master” and “slave” with “controller” and “follower” respectively.

Enables applications such as product tracking where moves must be applied over a target in motion, automatically stabilizes pan & tilt applications, or allows arm end effectors to remain parallel to base while the mid arm section moves.

Phase offset moves may be incorporated to move a relative distance while in Mode Step or Mode Follow. This distance is based on internal encoder counts. Phase offsets are essentially a Move over a Move in Relative Position Mode. They allow positional adjustment in either direction while actively following the external encoder or pulse train. This method may be used to align gantries as well as control tension in roller feed applications.

Similar to Mode Follow, the motor follows an external encoder. However, the motor moves to given points in a Cam table proportional to incoming external encoder counts. Electronic camming can be thought of as a table of electronic gear ratios that change dynamically based on external encoder position as a point of reference. It is possible to create dwell points at the beginning or end of the Cam table to aid in easy cut-to-length applications.

Contouring Mode (Host Mode):

Contouring Mode allows for true multi-axis coordinated motion. Contouring Mode is typically used by CNC software packages to control multiple motors within a well-defined path. Highly precise motion may be achieved with potentially no diminished capacity regardless of the number of motors being commanded to move.

It is ideal for any applications requiring linear, circular, curve linear or spline paths.

Note: Contouring Mode typically cannot be commanded from a PLC. It is best suited for PCs or embedded controllers.

Modulo Count Mode allows the user to define maximum position counter rollover. Normally, the shaft position counter can run anywhere from zero to +/- 231. This means the motor counter will continuously increase in the positive direction and when it hits its maximum, it will instantly go negative and begin counting down to zero.

With Modulo Count Mode, the user can alternately set up a counter that will increase up to a given value and then roll directly over to zero and start counting up again. The count will never go negative, it will always be 0<=modulo value<= (Modulo Limit-1). This mode is especially useful in rotary pan or azimuth controls for targeting systems, radar, and camera bases. Combined with the CombitronicTM interface, multi camera surveillance systems may more easily pass off subject tracking from one pan & tilt to the next.

PML= 360 (Position Modulo Limit) maintain counts between 0 and 359

PMT= 270 (Position Modulo Target) take shortest path to Target Position.

DE/Dt: Rate of Change of Position Error Limit (Derivative Error Limit):

DEL (Derivative Error Limit) provides the safest fast-means to fault a motor on sudden changes in load or detection of human interference.

The purpose of this Limit is to act as a look ahead on position error. Instead of just triggering on a raw following error of how far behind in a move the motor may be, the processor is looking at how fast that position error changes. DE/Dt refers to the dynamic rate of change of position error. This results in an instant release of energy and safer operation and less chance of damage to equipment or injury to machine operators.

Under normal servo control position error limits, if the load collides against an object, the motor will not fault until the position error limit is reached. As a result, current and torque applied will increase until that condition is met. By adding an additional derivative limit on position error, the servo will fault out within microseconds of contact with the object.

Example:

DEL=VT ‘Set limit to commanded speed

If dE/dt equals commanded velocity, then the motor just hit a hard stop. Normally, the motor would have to continue applying torque until the normal position error is exceeded. However, if DEL (DE/Dt limit) is set to target velocity (VT), then the controller would error out immediately upon hitting a hard stop without any wind-up whatsoever.

Derivative Error Limit (Rate of change of position error limit)

This feature quickly detects jams for safer operation and less chance of damage to equipment or injury to machine operators.

Jaw stops immediately upon making contact with metal for minimal product deflection and maximum balance to each side.

Cam Mode with Advanced Capabilities

Note: For this section, refer to the figure in Cam Mode (Electronic Camming) above.

Electronic camming is similar to mechanical cams in that for a given controller rotating device, a follower device tracks the speed and moves through a fixed profile of positions. In electronic camming, the profile is a look-up table of data stored in the follower motor. Cam data can run from CPU RAM or Flash. Extra cam data may be stored in EEPROM as well. Cam Mode data may be run using either fixed segment length or variable segment length.

- RAM storage: 1 Cam table

- 52 fixed length data points, 35 variable length data points

- Flash storage: 9 Cam tables

- 750 fixed length data points, 500 variable length data points

- EEPROM: Up to 8000 points total may be stored and move to flash or RAM

Powerful & Advanced Capabilities

- Multiple profile tables may be stored & called upon when required

- Dynamic tables can be created in real time for cases where amplitude or frequency and even actual specific points may need to be changed on the fly

- The controller signal may be either an external encoder input from another motor, or it may be from an internal virtual axis encoder signal

Use Cam Table to Control Entire Machine Process

Data is in the form of follower positions and controller position deviations. Table data may be fixed controller position deviation where only follower data is stored or may be variable segment controller data and follower data combined. In addition, each cam data point has an additional 8 points of control data. This control data may be used to define interrupt Status Bits for controlling I/O or move events, as well as defining a given point as linear, or curvilinear spline points.

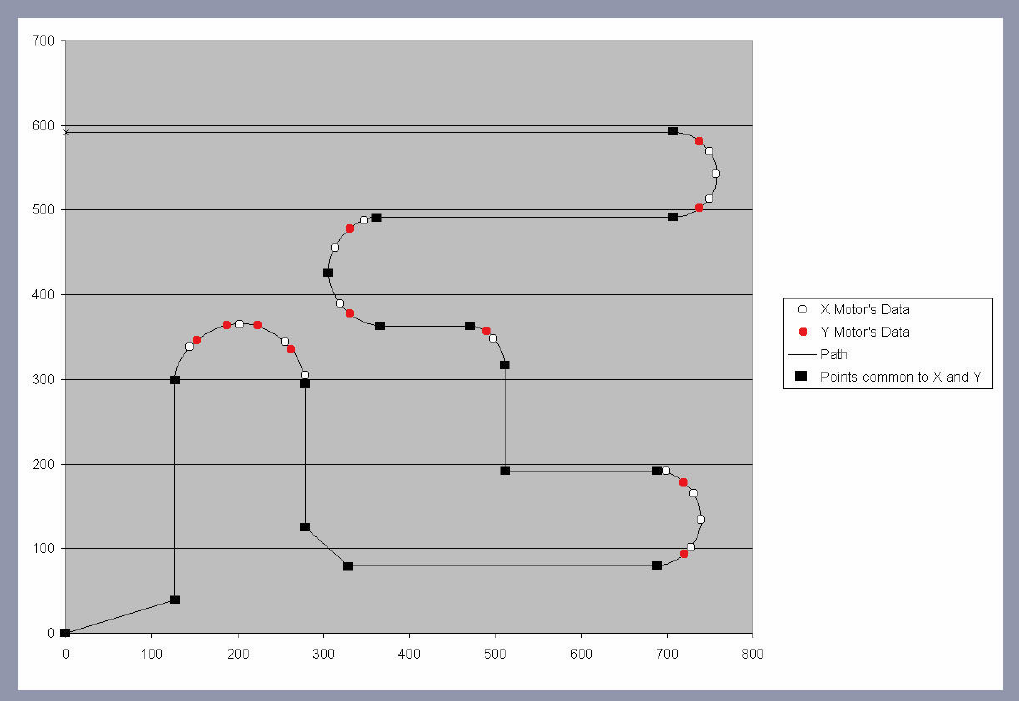

All cam tables may be run as standard linear interpolation or a modified spline algorithm. When running in Spline Mode, the data points may be greatly reduced. The following figure shows an X Y plot of cam tables running on two motors. While the original data was over 700 points, the final data was around 30 points in each motor.

The example data for motor 1 is shown in the following table.

| CTE(1) | CTW(511,29900) |

| CTA(30,0) | CTW(509,32600) |

| CTW(0,0) | CTW(498,33100) |

| CTW(126,2600) | CTW(456,34000) |

| CTW(130,8200) | CTW(334,36500) |

| CTW(156,9100) | CTW(312,37200) |

| CTW(253,11200) | CTW(306,37900) |

| CTW(273,11900) | CTW(323,38700) |

| CTW(279,12500) | CTW(372,39800) |

| CTW(279,15700) | CTW(740,47200) |

| CTW(329,15800) | CTW(756,47800) |

| CTW(717,23600) | CTW(756,48400) |

| CTW(737,24300) | CTW(743,48900) |

| CTW(739,24800) | CTW(687,50100) |

| CTW(727,25400) | CTW(0,63900) |

| CTW(699,26100) | CTW(0,75600) |

Below is the Cam Display window in SMI that you see when importing data. Clicking the “Copy Simplified Points to Clipboard” button on the bottom left side of the Cam Display window in SMI results in the cam points listed in the previous table.

Flexible Approach

- Cam table data may be directly imported from a tab delimited text file or spread sheet

- Imported data in SMI can be written into a program, copied to the clipboard or directly written (live) into a motor

- Import function allows for optimizing data points for cubic spline interpolation